Delta Heating & Plumbing are leading the way setting new industry standards in restoring efficiency to your central heating system’s radiators, pipework and boiler with our latest “quad-magnet flushing technology” used in conjunction with our high flow power flushing unit ensuring the most efficient and powerfull cleaning process available. This makes sure you get the best value for your money, maximising the transferrable heat from your chosen fuel source gas, oil or solid fuel back boiler to your radiators and hot water cylinder.

Radiators can warm up quicker, reduction in system noise, increasing the life of the system, improving system reliability and helping to lower energy bills.

WHAT IS THE BLACK SLUDGE IN RADIATORS?

When taking a radiator off the wall for decorating, have you ever wondered what is the black sludge in the radiators? Plumbers and heating engineers often refer to the black sludge, which has a resemblance to waste oil as ‘magnetite’.

Magnetite is a build up of rust that has fallen from the inside of the radiator. Black sludge is iron oxide, it also has small sharp particles inside. It also comes from cast iron heat exchangers and circulating pumps. If not managed this will eventually become so thick it will stagnate and lead to the restrictions and blockages

What is Powerflushing?

As soon as a heating system is installed and filled with water, deterioration can begin to take place. The combination of water, air and a mixture of metals can result in corrosion, sludge formation and scaling of boilers and heat exchangers.

When installing a new oil boiler all boiler manufacturers require the old system to be chemically cleaned and flushed with a power flushing machine. If a system is not professionally power flushed this could invalidate your warranty on the new boiler. All boiler manufacturers carry this warning in small print in the warranty package. When the system is not cleansed and power flushed, it could mean your boiler will not run at its full capacity and efficiency, wasting €€€€’s on your heating bills.

These issues are usually highlighted with the following symptoms:

• Your central heating system is slow to heat up.

• Some radiators are cold at the bottom.

• Some radiators require frequent bleeding.

• Irritating noises from the boiler.

• Repeated pump or valve failures.

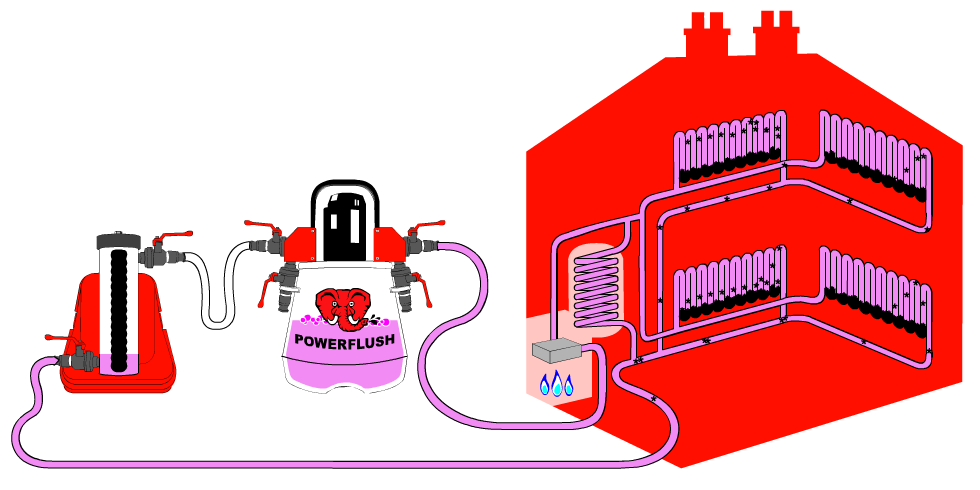

Powerflushing is the fastest and most effective way to flush heating systems with minimal disruption and dismantling. It is the process which is used to clean heating systems using water at high velocity, but low pressure. It usually involves the addition into the system of powerful cleansing chemicals and mobilising agents. These chemicals and agents clean heating systems by removing flux, sludge and other debris which has collected in the heating system over the years. We also use powerful twin magnacleanse filters in conjunction with the flushing unit to ensure the removal of all magnatite. It is prudent to power flush a heating system immediately before fitting a new boiler to an existing system to prevent possible future problems. This is a warranty requirement from all Boiler Manufacturers.

How is Power flushing carried out?

The power flushing pump is connected to the system across the flow and return pipework specialist chemicals are pumped at a higher than usual velocity across each radiator individually and through the hot water cylinder coil. The result is the magnetite, more commonly known as sludge, slowly being broken down and suspended in the rapidly moving water. All debris and corrosion is then dislodged by the flow generated by the pump. This water is then passed over two large magnets in the flushing machine which mobilise the unwanted debris and prevent it from being reintroduced into the system. The dislodged debris and corrosion is then flushed through the pump’s drain. At the same time, the pump fills the system with fresh water from the connection to the cold water main. Then the pH levels in the system is neutralised and a corrosion inhibitor is added and circulated throught the system to improve efficiency, help extend the life of the system and prevent future blockages.

HOW OFTEN DO I NEED TO POWERFLUSH MY HEATING SYSTEM?

If the system has been well maintained, inhibitor being topped up yearly, most systems only need power flushing every 5-6 years.

When should I Powerflush?

Prior to fitting a new boiler (to validate the boiler manufacturer’s warranty)

Cold or partially cold radiators (cold on the middle/bottom edge)

Radiators that need to be bled regularly (build up of air)

When radiator water is dirty (black magnetite)

Kettling noises from boilers

Noises in pipes

Circulating pump failure

Pin hole in radiator

There are thousands of ageing central heating systems with circulation and boiler noise problems caused by accumulations of sludge, corrosion, debris and scale. Some clients try to remove sludge by installing chemical mobilising agents directly into the system and then repeating the process some weeks later. This is fine for systems that only have a minimal amount of debris. However, for systems that are suffering from sludge, it really is best to get your system power flushed. Power flushing will cure most circulation problems.

Boiler manufacturers recommend that a heating system should be power flushed immediately before a new boiler is fitted to an existing system. Some manufacturers even make the boiler’s warranty conditional on this. When a new boiler is fitted, the system alterations and high efficiency of the new boiler can dislodge accumulated debris which has been in the system for years. This is why boiler manufacturers are reluctant to carry out warranty repairs where it is suspected that the fault has been caused by debris and sludge in the system. Only by power flushing can you be sure that a system really is clean to the standards demanded by modern high efficiency boilers and heat exchangers.

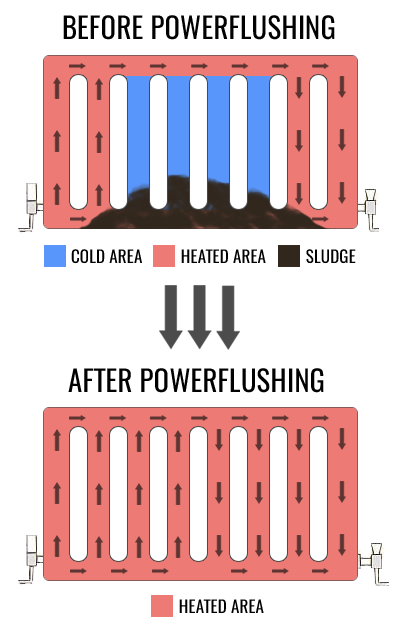

Radiators that are cold or partially cold are often this way because there is sludge trapped in them. The sludge tends to sink to the bottom of the radiator. This is why radiators can sometimes feel cold at the bottom and hot at the top. If the sludge is removed by power flushing, then the water is able to circulate around the whole radiator rather than just the top part of that radiator.

Powerflushing, Frequently Asked Questions FAQ’s?

HOW LONG DOES A POWERFLUSHING TAKE?

Depending on the size of the system being Power flushed its generally completed the same day.

DO YOU GUARANTEE YOUR WORK?

Yes we do guarantee our work. After power flushing we issue a certificate to confirm cleanliness and pH levels within your system conform to industry standards, boiler warranty and that an appropriate corrosion inhibitor has been added.

DO I NEED A POWERFLUSH IF I AM GETTING A NEW BOILER?

YES, for your boiler manufacturer to guarantee the boiler and as part of your warranty they need to know that your new boiler is being installed into a clean system. We can issue you with a certificate stating that the system has been power flushed.

IF I AM CHANGING MY RADIATORS DO I NEED TO POWERFLUSH?

YES it will still be beneficial as you are putting new radiators onto the existing sludged up pipework, so after the new radiators are installed, we will flush out your system and balance all of your radiators to help you with getting the maximum efficiency out of the system.

CAN AN OLD SYSTEM BE POWERFLUSHED?

YES, our equipment uses less pressure than the mains water so does not risk your system and by power flushing old systems it keeps your heating more fuel efficient.

Check out how we can restore your heating system’s efficiency and performance by power flushing, call now for a quote and to find out how we can help.

- Thermal Imaging Survey conducted, before and after..

- Enhanced energy-efficiency.

- Improved system reliability.

- Potentially lower energy bills*

- Reduced likeliness of boiler breakdown.

- Validate warranty of new boiler installation

- Could increase system lifespan.

- Radiators balanced properly.

- Radiators can warm up quicker.

- Better quality of heating and hot water.

- Easier on circulating pumps, consuming less energy

- Reduced noise from boiler and radiators.

If you’d like to speak to the Delta Heating & Plumbing’s experts about how Power Flushing could help fix your problem radiators and we’ll be glad to talk you through your options and arrange for an appointment with one of our experienced Service Engineers. In the long term, Power Flushing reduces the risk of breakdowns, noisy boilers, extends life pumps and cold spots on radiators. That means warmer radiators and cosier days ahead.